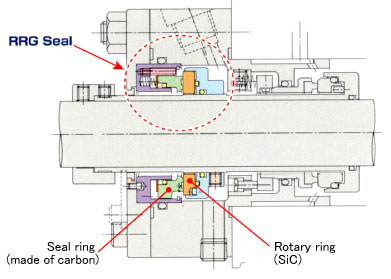

Pillar RRG mechanical seal is used as secondary seal in tandem seal. Groove on the seal face reduces load to the seal and contributes longer life.

Features

- Environment friendly seal unit

Pillar RRG seal is an environment friendly seal unit which will not allow a small amount of leak from primary seal to be diffused in the atmosphere. - Seal system requiring no reservoir

Pillar RRG seal doesn’t require reservoir, it can save the space and reduce the cost. - Long-time dry sliding realized

The seal ring is grooved for reduction of load and is impregnated with special lubricant, it is applicable to the dry running. - Space-saving/static type cartridge seal

Application

- Process pump

Basic Construction

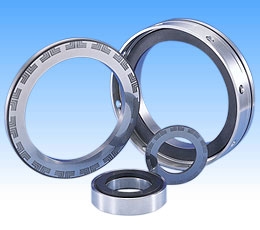

The Pillar PPG (Pillar Phoenix Groove) seal is Hydrodynamic dry gas seal designed with non-contact, which seal surface is uniquely grooved to use the dynamic pressure effectively by the multi-barrier.

It is applicable to a wide range of applications from centrifugal compressor to the steam turbine and blower.

Features

- Multi-groove type, assuring stabilized sealing performance

The divided multi-groove serves to maintain the desired parallelism between seal surfaces, and further to minimize the change in leak rate. Besides, the leak rate in this case is approx. 1/1000 of that for labyrinth seal, as the clearance between seal surfaces is minimal or several micrometers. - Minimized power consumption

Since the power is used only for shearing gas at seal area, the power consumption is extremely limited as compared with contact seal. - Space-saving cartridge type

The PPG seal is a cartridge type seal which rotary side is integral with the static side, allowing the seal to be handled easily. - Applicable to rotation in both directions

Since the groove is bilaterally symmetric, it is applicable regardless of rotating direction.

Application

- Turbine, blower

Basic Construction